Hot Isostatic Pressing (HIP)

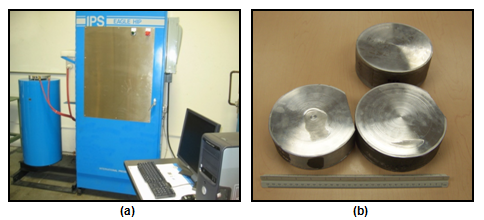

Hot isostatic pressing (HIP) is a manufacturing process that helps reduce the porosity of metals and can be used to influence the density of ceramic materials. HIP helps to improve a material’s mechanical properties and workability. The samples are subjected to high temperatures and gas pressures in a high pressure containment vessel.

Aegis Technology can deliver HIP-pressed billets ranging from 1 lb. to 100 lbs.

These billets can be used for experimental, prototyping, and commercial applications. HIP billet specifications are:

- Diameter: 4 – 12 inches

- Length: 6 – 12 inches

- Pressure: Up to 3000 PSI

- Temperatures: Up to 1400°C

(a) Hot Isostatic Pressing (HIP) Machine

(b) Consolidated SiC nanocomposite using Hot Isostatic Pressing (HIP)