High Energy & Cryogenic Ball Milling

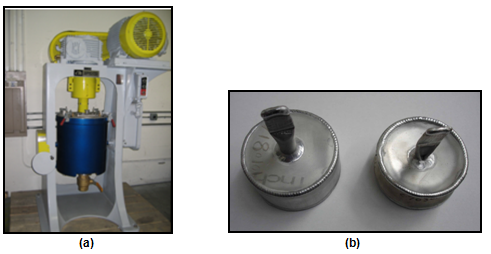

Aegis Technology uses high-energy ball milling, also referred to as mechanical attrition or alloying, including cryogenic ball milling, to synthesize a variety of nanostructured materials. The ball milling induces heavy cyclic deformation in powders and promotes the formation of nanostructures by the structural decomposition of coarser-grained structures as a result of severe plastic deformation. Cryogenic ball milling (or cryomilling) can reduce oxygen contamination and minimize heat generated during the milling process. This favors fracturing over welding of ductile materials during the milling process.

The nanomaterials that are synthesized using cryogenic ball milling, are constituents for protection coatings, high-strength alloys, composites, nanocomposites, brazing alloys, magnetic devices, and thermoelectric devices. Aegis Technology also provides consolidation of various bulk nanostructured materials including high-strength alloys, composites, magnetic materials, thermoelectric materials, and transparent ceramics.

Aegis Technology uses cryogenic ball milling, which involves low temperature grinding of materials, for synthesizing nanopowders. The ball milling takes place at -180 deg C, under liquid nitrogen atmosphere. The materials that can be ball milled in a cryogenic environment include the following:

- Aluminum (Al)

- Brazing materials

- Copper (Cu)

- Magnesium (Mg)

- Magnetic materials

- Nickel (Ni)

- Silicon Carbide / Aluminum nanocomposites

- Silicon Carbide / Magnesium nanocomposites

- Thermoelectric materials

- Titanium (Ti)

Consolidation

After cryomilling the materials, Aegis Technology provides subsequent processing including the consolidation of the nanopowders into bulk nanostructured forms and pastes for coating or other surface applications.

(a) Cryogenic Ball Milling (Cryomilling) Attritor

(b) Consolidated SiC nanocomposite using Hot Isostatic Pressing (HIP)