Analysis, Materials Testing, Modeling, and Simulation

Analysis

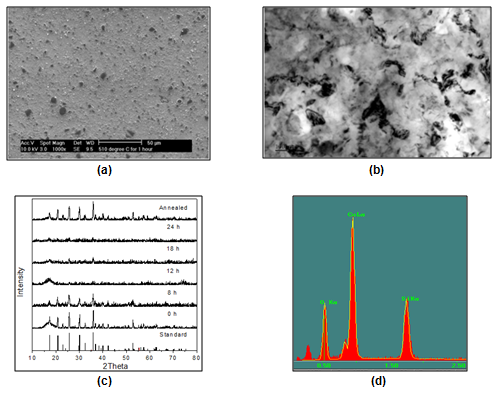

In order to analyze various types of nanomaterials and nanocomposites, Aegis Technology uses the following analysis techniques and equipment:

- Chemical Analysis

- Differential Scanning Calorimetry Analysis (DSC)

- Energy Dispersive X-Ray Spectroscopy (EDS/EDX)

- Microhardness Measurement Analysis

- Scanning Electron Microscope (SEM)

- Transmission Electron Microscope (TEM)

- X-Ray Diffraction Analysis (XRD)

(a) SEM Analysis

(b) TEM Analysis

(c) XRD Analysis

(d) EDS Analysis

Materials Testing

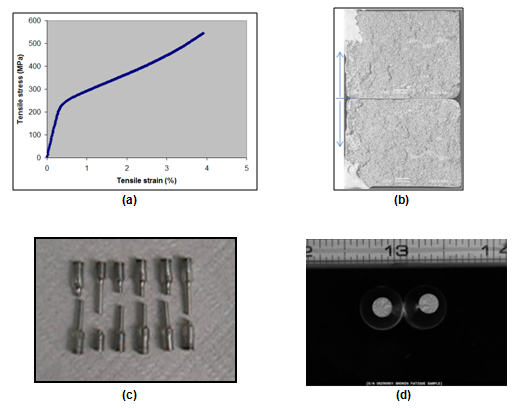

Aegis Technology uses the following testing methods to evaluate the integrity of nanomaterials and nanocomposites:

- Bending Strength

- Compression

- Creep

- Fatigue

- Fracture

- Mechanical Strength

- Tensile Strength

(a) Tensile Stress versus Tensile Strain

(b) Fractography Analysis

(c) Tensile Specimen Testing

(d) Axial Fatigue Testing

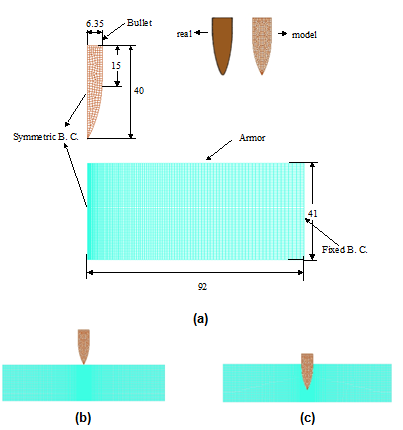

Modeling and Simulation

Aegis Technology has years of experience in modeling and simulation. We use modeling and simulation to analyze the performance of nanomaterials and nanocomposites for a variety of applications. We have conducted modeling and simulation using computer software including LS-DYNA for evaluating the impact and high-speed deformation in nanomaterials and nanocomposites. In addition, we have evaluated the dynamic impact, armor penetration, and ballistic performance capabilities of various nanomaterials and nanocomposites including alloys, ceramics, and composites.

(a) Model of machine gun bullet and armor material

(b) Modeling and simulation of 50 caliber bullet reaching armor surface

(c) Modeling and simulation of 50 caliber bullet penetrating armor